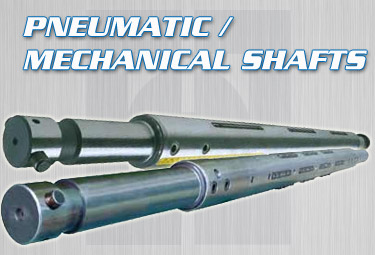

Lug Pneumatic/Mechanical Shaft Components

More InfoPM-1000

MS-1000

- Custom journals.

- Corrosion-proof air valve can be located on side or at end of pneumatic mechanical shaft.

- Center rod.

- Tempered steel housing.

- Hardened steel lugs provide reliable grip force on all core types.

- Cams.

- Individual cam springs force independent lug rise; shaft grips consistently even when core diameter varies.

- Pistons.

- Proprietary fasteners with hardened steel expanding bushings provide strong connection without requiring a press fit

- Jacking screw at shaft end serves as mechanical override (pneumatic mechanical shaft).

Features - Advantages - Benefits

Important characteristics of PM and MS core shafts. Click here

PM-1000 Pneumatic/Mechanical Lug Shafts

Mechanical activation and fail-safe grip, with the convenience of air powered lug retraction. Click here

MS-1000 Fully Mechanical Lug Shafts

The most aggressive core shaft on the market today...for high speed and/or heavyweight applications. Click here

DLB-2000 Carbon Fibre

Expanding Core Shafts

High strength, lightweight air shafts reduce the chance of operator lifting injuries. Click here

DG-2000 Expanding Core Shafts

Lug style shafts with a steel or aluminum housing. Click here

SR-2000 Strip Core Shafts

Ideal for multiple slit rewind applications. Click here

Differential Rewinding Shafts

Double E offers two types of differential shafts to ensure optimal performance. Click here

RS-2000 Expanding Reel Spool Core Shafts

Large diameter shafts for reel spool applications. Click here

PM-1000 Pneumatic/Mechanical Lug Shafts

The PM–1000 pneumatic mechanical shaft utilizes a unique “air-down” gripping system which combines the benefits of concentric expansion with the convenience of air retraction. Lugs grip the core automatically when the shaft is vented; lugs collapse when air is added.

MS-1000 Fully Mechanical Lug Shafts

The MS–1000 mechanical shaft provides the best gripping force of any core shaft available today. It is designed with greater structural strength and a powerful expansion mechanism to handle the heaviest roll weights at high speeds. No compressed air is needed to operate this mechanical shaft, yet expansion and retraction is easily accomplished with just five (or fewer) turns of the activating screwFeatures and Benefits

PM (Pneumatic/mechanical shafts) and MS (mechanical shafts) share many important and distinct characteristics which become especially beneficial when web speeds are fast and roll weights are heavy.

- True Concentric Expansion

- Mechanical activation locks gripping lugs in the expanded state, actually lifting and centering the roll. This true concentric expansion minimizes roll bounce and vibration – even in high-speed and/or heavyweight applications.

- Fail–safe operation

- With lugs mechanically locked, the shaft cannot stop gripping during production.

- Independent lug action

- Each lug set is activated by separate cam springs, allowing the core shaft to grip uniformly even when core variations are present, or when cores aren’t covering all lug sets.

- Proprietary journal connection

- Proven “scrivet fastening system” ensures durability at journal connections without requiring a press fit.

- Positive lug retraction

- The mechanical system ensures lugs retract fully so shaft never

sticks in cores.

If you need a high strength, lightweight, shaft solution, please consider

Click on this link for more information for complementary safety chucks.