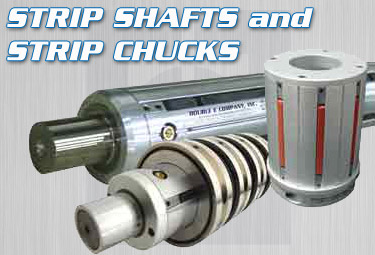

Expanding Strip Shaft

More Info- Multiple external expansion elements to grip the inside diameter of any core material.

- Gripping elements are activated by simultaneously inflating bladders with a single air valve.

- While bladders rarely fail (because of our proprietary material and metal protection strip), the process to replace one is simple and quick. Likewise, the gripping element can be replaced easily by loosening a single set screw in the clamping unit.

- Hard rubber elements are standard; silicone and aluminum are available to suit various applications.

- Minimizes core distortion and wall damage.

- Economical to purchase and maintain.

3-inch Expanding Strip Shaft

6-inch Expanding Strip Shaft

SRC 2000 Strip Chucks

Expanding strip chucks can be used in cantilevered or shaft-mounted applications. Click here

Knife Shafts

High precision stainless steel shafts for gripping the ID of knife anvils in slitting operations. Click here

Differential Rewinding Shafts

Double E offers two types of differential shafts to ensure optimal performance. Click here

DLB-2000 Carbon Fibre

Expanding Core Shafts

High strength, lightweight air shafts reduce the chance of operator lifting injuries. Click here

CF-1000 Carbon Fibre Through Shafts

Non-expanding lightweight shafts for providing through-roll support using air bladder chucks. Click here

PM-1000 Pneumatic/Mechanical Lug Shafts

Ideal for high speed and/or heavyweight applications, with the convenience of air-powered lug retraction. Click here

MS-1000 Mechanical Lug Shafts

The most aggressive gripping shaft for high speed or heavyweight applications. Fully mechanical operation. Click here

RS-2000 Expanding Reel Spool Core Shafts

Large diameter shafts for reel spool applications. Click here

SRC-2000 Strip Chucks

- Any length and any diameter - used in through-shaft or cantilevered applications.

- Chuck body provides solid strength which prevents roll bounce and vibration.

- Simple clamping collar facilitates repositioning of the chuck.

- Bladders are tough, dependable, and easy to replace.

- External elements come standard as rugged silicone, but other materials such as aluminum and hard rubber are also available to suit various applications.

Knife-Shafts

- Tight-tolerance external element shaft which holds anvils or knives precisely in place for slitting operations.

- A single air valve is used to supply air to the bladders.

- When the bladders expand, they force the gripping elements to grip the interior diameter of the knives, preventing axial movement and ensuring exact, consistent cuts.

- No tools are necessary to secure the knives.

- Chrome-plated, polished steel for added precision between the shaft body and the interior diameter of the knives.

-

All of the other characteristics of the knife shaft are similar to the standard SR–2000 strip shaft.

If you need a high strength, lightweight, shaft solution, please consider

Click on this link for more information for complementary safety chucks.